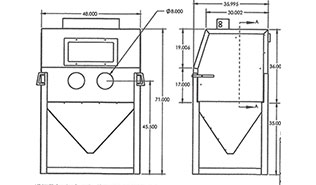

The RB4836DP is the ultimate Direct Pressure blast cabinet for medium to large sized objects. The RB4836 is a laser cut and hand welded 12 gauge industrial blast cabinet. No seams or rivets, all media stays in the cabinet. With a 1 cube pressure vessel, micro metering valve and 3/4 inch piping.

Why Choose a Direct Pressure Blast Cabinet?

Direct pressure blast cabinets deliver a high-velocity, direct-pressure stream of abrasive media at a surface. This provides both the power and speed needed for industrial blasting and removing caked-on coatings. You can quickly strip away heavy layers of paint, rust, scale, and corrosion from a surface using a direct pressure dry blast cabinet. Direct Pressure cabinets are much faster than siphon cabinets when blasting at less PSI pressure.

Direct Pressure Blasting vs Suction Blasting

Both siphon systems (suction blast cabinets) and direct pressure blast cabinets force blast media through a blast nozzle. Direct pressure cabinets use a pressure pot, where abrasive media and compressed air are mixed, and this is forced out through the nozzle.

Suction cabinets use compressed air fed to a suction gun to pull abrasive through a separate hose (a suction hose), where it is mixed in the suction gun, and forced out through a blast nozzle. The suction gun is able to pull the abrasive through the suction hose by accelerating compressed air through an orifice creating vacuum.

Suction blast cabinets generally cost less to purchase and set up, but have lower productivity than a pressure blast cabinet. Direct pressure blast cabinets use more air (CFM), but increase productivity, as blasting and stripping is more aggressive. With pressure blast cabinets, you will have to replace parts like the blast nozzle more frequently, as they wear out a bit quicker.

Another advantage of direct pressure blast cabinets is that you will be able to use heavier blast media than in a suction cabinet.

Why Our Direct Pressure Blast Cabinet is second to none.

The pressure blast cabinets from Raptor Blaster have been designed for heavy production use, where high work output is required.

All Raptor Blaster Cabinets are laser cut and hand welded in the USA. No seams, no rivets. All abrasive blast media will stay contained in the blast cabinet during operation.

You Might Also Like

RB4836 Industrial Media Blasting Cabinet

The RB4836 is the ideal blasting cabinet for medium to large objects. Comes standard with a 100 CFM can style dust collector or upgrade to a hard shell cartridge 400 CFM dust collector. Dual doors. 36″ deep, 48″ wide, 75″ high.

RB900DP Direct Pressure Blasting System

A complete Direct Pressure Blast System which incorporates a 1.5 cube Blast Pot with a high quality Micro Metering Valve, RB900 Reclaim and RB900 Cartridge Style/Timed Reverse Pulse Dust Collector into the one unit.