What kind of maintenance costs can you expect for a wet blast cabinet?

Specifically, how much does it cost over the course of a year to run a wet blast cabinet?

In this article, we’re looking at the secondary costs associated with a wet blast cabinet (sometimes called a vapor blast cabinet). We’ll examine the estimated cost of replacement parts and other needs like abrasive blasting media and energy consumption.

How Wet Blasting Differs From Dry Blasting

The biggest difference between traditional dry blast cabinets and wet blasting cabinets is how fast the components wear out. With dry blast cabinets, the replacement parts, like the nozzle and hoses, wear down about eight to ten times faster than in a wet blast cabinet. Reason being, in a wet blast cabinet, the water is used a propulsion medium instead of compressed air.

Depending on how much you blast, and the hardness of the media you use, this might vary. But generally, the annual cost of replacement parts will be much lower in a wet blast cabinet vs a regular abrasive blast cabinet.

Let’s look at how often you can expect to order components.

Sandblasting Gloves

If you are wet blasting five days a week, you can expect to purchase a new set of sandblasting gloves about every 6 to 8 months. Sandblasting gloves come in different sizes, denoted by length and diameter. The deeper the cabinet interior, the longer the glove. The wider the diameter, the larger the arm can fit into the gloves.

Sandblasting gloves are usually made from rubber, neoprene, or other synthetic rubber polymers.

A pair of heavy-duty gloves will usually cost between $40 and $50.

Blast Cabinet Window

You can expect to replace the window glass on your wet blast cabinet about once a year. You may also eventually need to replace the gasket and underlayment. This will usually cost somewhere between 45 and 65 dollars.

Blast Hoses

About every year or two, you may need to buy replacement hosing. You can expect to pay between 50 and 160 dollars for a fifty-foot section of 1/2″ ID hose.

Blast Nozzles

There are a few different types of blast nozzles. Ceramic nozzles are the least expensive, also wearing out the fastest. Tungsten carbide nozzles are more durable than ceramic. Seven tungsten carbide nozzles are equivalent to a hundred ceramic nozzles. Silicon carbide and SiANON nozzles are similar to silicon carbide, but lighter in weight. Boron carbide nozzles are the most expensive, but also the most durable, lasting about seven times longer than tungsten carbide.

Ceramic nozzles are okay for softer media and lower production shops. For heavy production shops, these types of nozzles are not cost efficient. Ceramic nozzles usually run between $6 and $20 dollars each.

Tungsten carbide nozzles are much more durable, and can handle abrasive media with a higher Mohs hardness. These usually cost between $30 and $120 dollars. Silicon carbide and SiAION nozzles can run between $100 and $135 dollars apiece.

Boron carbide nozzles are the most durable and resistant to wear, lasting about seven times longer than tungsten carbide, and twice as long as silicon carbide. These can cost between $40 and $140 each.

Below is a chart showing the estimated life cycle of each nozzle material for different abrasive media types.

| Estimated Service Life in Hours | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nozzle Material | Steel Shot / Grit | Glass Bead/ Crushed Glass | Aluminum Oxide | |||||||

| Ceramic | 20-40 | 10-30 | 1-4 | |||||||

| Tungsten Carbide | 500-800 | 300-400 | 20-40 | |||||||

| Silicon Carbide | 500-800 | 300-400 | 50-100 | |||||||

| Boron Carbide | 1500-2500 | 750-1500 | 200-1000 | |||||||

Abrasive Blast Media

Each type of abrasive media has a different life cycle and cost. For a comparison of the pros and cons of each media for a specific job, see our article on choosing the right abrasive media.

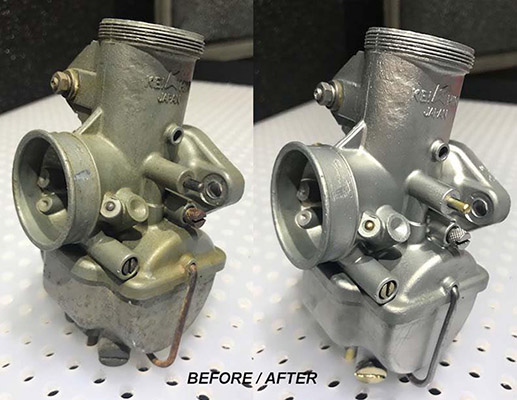

For stripping factory coatings, corrosion, and grime from automotive and motorcycle parts, we have found a mixture of glass beads and sodium bicarbonate works well. This mixture strikes a great balance between stripping efficiency and leaving the blasted surface unetched.

Depending on the type of media you use for your blasting application, your costs will vary.

Summing It Up

Dry blasting cabinets chew up components like hoses, nozzles, and windows much quicker than wet blast cabinets. The water in vapor blast cabinets acts as a buffer between the media and blast cabinet components, slowing the deterioration.

If you wet blast on a regular basis, you can expect the following costs over the course of a year.

Sandblasting gloves: $40-50

Blast Cabinet Window/Components: $45-65

Blast Hose (each one to two years): $50-160

Blast Nozzles: $60-280

Abrasive Media: Varies