The RB3630S is a heavy duty, industrial-use wet blast cabinet. Like all our sandblasting cabinets, our vapor blast cabinets are 100% laser cut and hand welded. Constructed with 12 gauge stainless steel, the RB3630S Wet Blast Cabinet is built for durability and efficiency.

The wet blast system in this cabinet, (often referred to as a slurry pump system), delivers a mix of blast media and water to the blast gun. There, compressed air is introduced to accelerate the abrasive media to the blasted surface. This is sometimes known as vapor blasting.

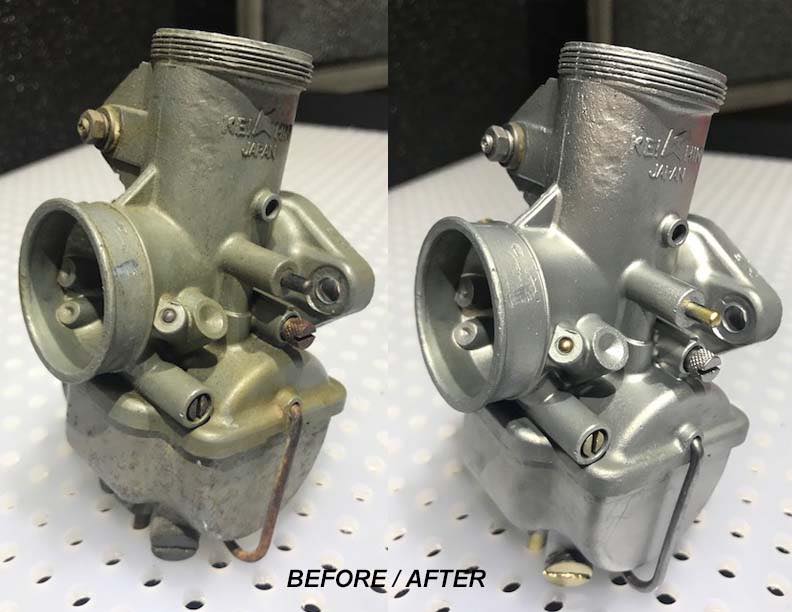

This process creates a very clean surface, much like the high impact of conventional dry blasting processes, but with a more delicate finish.

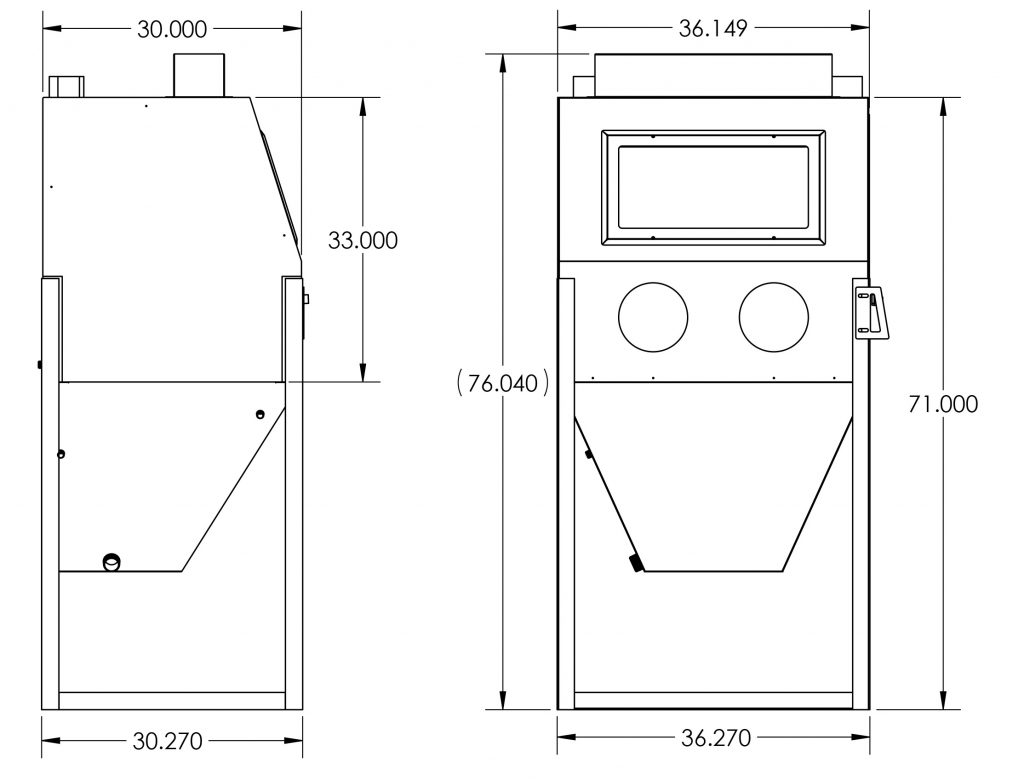

The footprint is 36.27″ by 30.27″. Check out the before and after pics of this part after we ran it through our slurry blaster. Quite a difference!

The RB3630S Slurry Wet Blast Cabinet is similar to the larger RB4836S Slurry Blaster, but made for shops where there is less floor space.

Our slurry blast cabinets come with a two year limited warranty.

You Might Also Like

RB4226 Industrial Abrasive Blasting Cabinet

See why the RB4226 is the best blasting cabinet for small to medium sized objects. 14 gauge steel body, 10 gauge steel doors. Laser cut and hand welded in the USA. Dual side doors, plus a front door for ease of use.

RB4836S Slurry System Wet Blast Cabinet

The RB4836S is a heavy duty, industrial-use slurry wet blast cabinet. 100% laser cut and hand welded. Constructed with 12 gauge stainless steel, the RB4836S Slurry Wet Blast Cabinet is designed for heavy-duty wet blasting. Two year limited warranty.